Washing is a pre-treatment for the piece’s preparation to the following painting. Through chemical aggression, the piece’s surface is prepared to allow the optimal finishing of the following treatments.

Washing booths and tunnels are designed to work with water-based detergents, thus combining chemical, thermal and mechanical action, in order to guarantee excellent results and eliminate all traces of impurities or dirt.

Over the years Eurotherm has developed a series of washing systems capable of meeting the most varied needs to wash and degrease products of any shape and size.

Custom washing booths and tunnels

Eurotherm is a leader in the production of reliable and flexible custom-made booths, tunnels and washing systems.

Eurotherm booths and tunnels have long been recognized for their ability to create innovative solutions that are entirely custom-made to meet your specific needs.

Eurotherm case studies

Over the years Eurotherm has distinguished itself in the field of washing booths by designing custom-made systems of great national and international importance.

Here are some examples:

Our worldwide experience makes us a leader in the field of washing booths.

Manual washing booth with skid

Manual washing booths are mainly used for washing operations of metal components or semi-finished products through a high-pressure water jet with phospho-degreasing solution and subsequent rinsing. In manual washing cells, pieces of different shapes and sizes can be washed simultaneously.

Our manual washing booths are made up of:

- self-supporting structure in painted metal carpentry;

- roof in pre-coated with polyurethane foam panels;

- floor entirely made up of a pedestrian or driveway grating (depending on loading requirements);

- inclined pit with recovery pit placed under the grating to convey the sprayed liquid.

The fumes and vapors created during washing by the high-pressure water jet are captured by the suction wall which, through droplet separators, divides the water molecules contained in the air. Air is free to escape from the extraction funnel, while the liquid reaches the liquid recovery pit directly.

The liquid collected in the pit is thus sucked and reintroduced into the corresponding skid recovery tank (one dedicated to each phase, in order to limit contamination between the various tanks as much as possible), to make it immediately available, supplying the water jet in a continuous cycle.

The advantage of this system, defined as a closed cycle, (zero rejet), is that there is no liquid waste in the sewer.

Our washing booths can be integrated with the rest of the machinery in a painting system through the aerial transport system of the pieces.

Washing booth with or without foundation

Eurotherm washing booths are mainly realized with construction work, by placing an inclined pit under the grating.

It is also possible to carry out the recovery of liquids without foundations, thanks to the use of a structure containing a series of small hoppers above ground.

The skid liquid treatment for manual washing booths

The skid has the dual function of filtering and continuous reusing the liquids sprayed in a closed cycle, the basic version consists of 3 phases:

- Degreasing with cold phosphodegreasing solution;

- 1st rinse with mains water;

- 2nd rinse with mains water;

It is also possible to integrate further phases that include:

- a further rinsing with osmotized or demineralized water;

- a final passivation treatment.

A series of accessories are also available such as:

- hot degreasing tank (to use phospho-degreasing liquids at 50/60°C);

- oil remover (to remove the residues of working with oils and greases from the degreasing tank);

- sludge remover (to prevent the formation of polluting deposits inside the tanks caused by heavier processing).

The automatic replenishment of the liquid through a reverse cascade takes place by setting up, for each phase, a 1500 liter tank, each with its own pump dedicated to the recirculation of the liquid in the filter (to remove impurities and sediments) and to the feeding of the high pressure water jet with a dedicated hydraulic circuit.

The structure at the base of the skid also acts as a safety containment tank, ensuring control of any liquid spillage from the tanks and reducing environmental impact.

The exclusive strengths of the Eurotherm washing booths with liquid recovery are:

- easy management and maintenance of the system, as minimal manual checks and maintenance are required;

- no liquid dispersion in the environment;

- waste reduction, as liquids can be used longer the contamination of the degreasing in the rest of the washes being limited;

- high customization of the washing cycle.

The washing portal

Inside the manual washing booths it is possible to insert a washing portal suspended from the ground that runs along the entire length of the booth. Through ramps of nozzles, the tunnel washes the pieces with a washing cycle that is similar to that of tunnels and automatic washing cells.

The washing portal is particularly suitable for washing large batches of similarly sized pieces, such as frames, door and window profiles, sheet metal, etc.

The advantage of this solution is its versatility, since within the same booth and with the same skid, depending on the type of pieces, it is possible to wash larger pieces by hand and wash smaller pieces automatically.

Download the data sheet of the washing booths for further information or contact us for a customized quote.

Washing cells and multistage automatic washing tunnels

These two types of washing systems are certainly the most widely used solutions in the world of industrial washing when high production rates are required.

Eurotherm washing cells and tunnels are made of stainless steel to ensure maximum resistance to degreasing liquids and increase the longevity of the machinery.

Washing tunnels and cells are designed to perform a surface treatment of the pieces in up to 6 phases:

- Phase 1: degreasing with hot phosphodegreasing solution (50/60°C);

- Phase 2: first rinse with mains water;

- Phase 3: second rinse with mains water;

- Phase 4: rinsing with recirculated osmotized water;

- Phase 5: pure osmosis;

- Phase 6: nanotechnological passivation.

Inside the washing booth the distribution of the jets coming from the spraying nozzles is oriented so as to hit entirely the surfaces of the pieces to be washed.

Below the washing booth there are pumps, hydraulic circuits and a pit with tanks for the recovery and reuse of washing liquids.

For each washing phase there is a dedicated accumulation tank that supplies the spraying nozzles in a continuous and automatic cycle through a reverse cascade. This solution has several advantages:

- minimization of contamination between the washes of each phase;

- optimization of the chemical products that are employed;

- no dispersion of liquid products in the sewer, with consequent reduction of environmental impact.

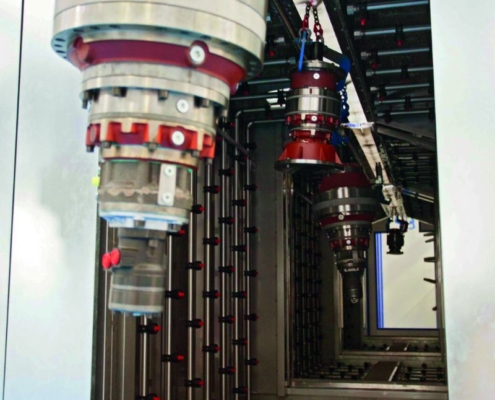

Eurotherm multistage washing cells

Our washing cells are designed to be perfectly integrated in manual painting systems.

An overhead conveyor deposits the parts to be treated in the wash cell and moves them throughout the wash cycle to ensure that the high pressure jets of the nozzles wash them perfectly.

The water that falls from the pieces under treatment is collected in the tanks below and recirculated through pumps and manifolds that feed the nozzles covering the entire surface of the inner tunnel.

Between the different spraying phases there are drainage or dripping pauses, suitable to limit the transfers between the tanks, in order to allow their own chemical properties to be maintained as long as possible.

Eurotherm multistage washing cells consist of:

– a structure made of stainless steel panels, press-bent, bolted and sealed together. This structure carries the spraying nozzles on the outside, it supports the conveyor runway on the top and is positioned above the treatment tanks.

– bottom in drainage sheets that collect and convey the liquids of each phase separately, through a self-propelled wagon, to the respective tanks.

– thick stainless steel tanks reinforced with steel profiles. For the “hot” tanks, mineral wool panels are also inserted in order to obtain greater thermal insulation.

– removable, washable and reusable metal filters to facilitate periodic maintenance.

– hatches for inspection and control of the cells;

– nozzles equipped with direct connections to the manifold of each cell through a dedicated pipe that is resistant to the chemicals that are used, connected to the supply pump.

– a hood equipped with droplet separators for the suction of the vapors formed during treatment and a centrifugal fan to convey the sucked fumes to the outside.

– an aspirator positioned outside and with the function of extracting all the vapors that are generated inside the cell during the washing cycle, which will also be used to take away also the vapors of the boiler.

In order to minimize the contamination of the different liquids sprayed during each washing phase, a number of precautions have been taken:

– the spray nozzles are fixed on the outside of the cell walls, facing inwards;

– all nozzle feeding pipes are dedicated exclusively to a single phase;

– all the nozzle feeding piping system is positioned externally, in order to keep the inside of the washing cell as free as possible from any encumbrance that could hinder the flow of the liquid on the walls.

[Download the technical data sheet of our multistage washing cells]

Single stage ecojet washing cell

Ecojet washing cells are designed for single-stage cold pre-treatment with Toran 3® without rinsing or pre-greasing.

This treatment guarantees excellent paint adhesion to various materials such as iron, aluminum and galvanized sheet metal. The ecojet tunnel, through low-pressure spraying (flow coating), covers the piece with a very thin film that promotes the adhesion of the coating, increasing the corrosion resistance of the coating cycle.

The system is a valid and inexpensive alternative to multi-stage phosphodegreasing if the semi-finished products to be painted are compatible with Toran 3® treatment.

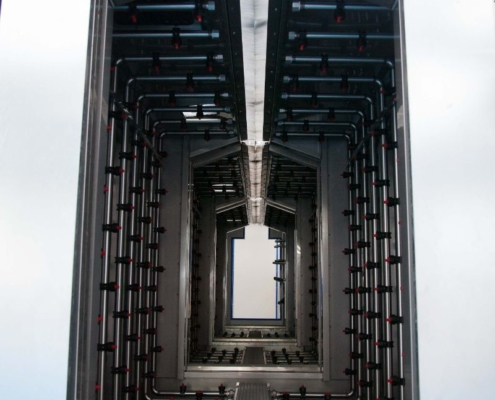

Eurotherm washing tunnels

Washing tunnels are integrated into automatic painting systems and are necessary to guarantee an excellent final result starting from the initial pre-treatment.

The various phases of treatment take place by passing the pieces through an automatic conveyor inside the tunnel where they are washed, using spray nozzles, from the various liquids in sequence before moving onto the next process, all without stopping.

Consequently, this is the fastest system for washing pieces but also the least flexible, since it is bound not only by the limits of the pieces’ shape but also by the coating cycle itself. Given the “in-line” nature of the system itself, it is therefore essential to develop the washing tunnel according to the goals and results that are being sought. This is where Eurotherm comes into play, not only as a system manufacturer, but above all as a strategic partner. Our technicians and engineers will be able to give you the best advice stemming from their vast experience in the field.

[Download the technical data sheet or visit the painting systems page for more information].

Multistage immersion washing systems

This is a washing system of pieces, generally very long metal profiles, which takes place by total immersion of the pieces inside special tanks through a basket moved by a dedicated overhead crane.

In Eurotherm we design and build this kind of system in a completely customized way, according to your needs.

[Download the data sheet for further information.]

Parts washer

Parts washers are standard automatic machines of different sizes with a basket and a series of nozzles inside, perfect for washing and degreasing many pieces of various sizes all together with excellent results.

Single stage hot washing machines

They are designed for spray washing, with water-based detergents, at a maximum temperature of 60°C. They are made of stainless steel and are particularly suitable for washing small objects with moderate weights.

[Download the data sheet for more information]

Two-stage hot washing machines

They have the same basic features of the single-stage washer but reach a maximum temperature of 70 ° C, the rotation of the basket is motorized and washing is performed in 2 stages: degreasing + rinsing. Depending on the model, it can also accommodate medium-sized pieces.

[Download the data sheet for more information]

Single-stage and two-stage hot parts washers for bulky parts

These booth-type parts washers share the same features as the previously-mentioned machines, but their larger size allows to wash even bulky pieces with a high weight, while maintaining a high standard of final cleaning.

[Download the data sheet for more information]

Rail-equipped or conveyor belt parts washer for high productivity

These machines are designed to load the pieces continuously, on a conveyor belt, by the operator or robot and are directly integrated in the production line. Made to measure, they can have one, two or three stages.

[Download the two data sheets for more information: Pdf(1) and Pdf(2)]

FAQs about Eurotherm washing plants and booths

What do Eurotherm washing booths consist of?

- modular washing booths or tunnel

- liquid recovery system and delivery to the high pressure washer or nozzles;

- suction wall;

- electrical panel;

- system for movement of the products.

What size are the washing booths?

In the technical data sheets the information about the dimensions of our systems are merely indicative because in Eurotherm we mainly realize customized booths and can adapt to any space constraint. Our technical team will counsel you best from design to testing.

What fields do Eurotherm washing booths work for?

Mainly in the industrial sector, metal carpentry, automotive, aeronautics, railway.

Which detergents should be used in Eurotherm washing booths?

Our booths and skids are compatible with most of the phosphodegreasing solutions available on the market, even the most aggressive. Our technicians will be able to counsel you best, studying the solutions that are best suited to your needs.

What are the washing cycle times?

The average duration of the washing cycle varies depending on several factors including the size, type of dirt, or material the pieces are made of, as well as the type of treatment performed. Generally speaking, the duration of the washing cycle of a 5-phase cell can vary from 10 to 20 minutes.

As far as in-line washing tunnels are concerned, the duration is established by the passage time of the conveyor inside the tunnel itself; in general, in automatic systems, it is calculated in terms of pieces per minute.

In manual washing booths the washing times are managed by the operator who, according to their experience and on the basis of visual controls, decides autonomously when it is time to pass from degreasing to rinsing and so on.

Are Eurotherm washing booths covered by warranty?

The booth and all its components are covered by warranty as per current regulations.

Does Eurotherm also design complete workflows?

We design and build wash booths and tunnels that are designed to be integrated into coating lines to ensure a complete workflow whether it is a manual or continuous line, depending on your needs.

Eurotherm creates innovative solutions to meet all needs.

Contact us and tell us about your business for a customized quote.