Zero-emission powder coating plant for Fit Out

Eurotherm has recently installed a new zero-emission powder coating facility for Fit Out, a leading UK interior fit-out company.

Paint storage container: which paints last the longest?

In the first photo an example (real!) of “creative” paint storage, in the second our containers equipped for storage

Automotive Lens Annealing oven

For a major European company specializing in automotive lighting systems , we recently installed a Annealing oven oven designed to ensure maximum efficiency and quality of lens Annealing treatment.

Monoblock Annealing oven in a confined space

This is a very special Annealing oven for Eurotherm because it required addressing three crucial aspects in customizing the system:

1. To build a high-precision Annealing oven.

Painting Plant for the Railway Sector: Eurotherm for Sustainable Mobility

For the historic Alstom site in Savigliano di Cuneo, a global leader in the railway sector, we recently created a cutting-edge liquid painting system.

The internalization of painting in the railway sector for Movinter

The European Green Deal has important goals: by 2050, it wants to reduce CO2 emissions from transport by 90%. Clearly, rail transport will benefit , both for goods and people. A fact confirms this: the European Commission plans to triple high-speed rail traffic by the same date, with the aim of achieving a single trans-European, integrated and multimodal rail network involving land, sea and air transport.

Manual washing cabin with roof opening

Eurotherm has recently created a new manual wash booth with a roof opening to facilitate access of the parts by overhead crane and with sliding doors.

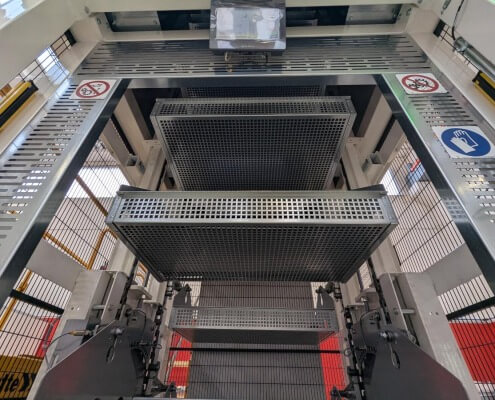

Little space? Here is the telescopic powder coating system!

At Eurotherm we have a credo: it is not the company that has to adapt to the paint shop, but the paint shop that has to adapt to the plant. A belief that we have taken to another level with this innovative telescopic powder coating plant !

Automatic in-line powder plant with continuous feed

There's a little bit of Eurotherm in DIY stores all over Europe now! We recently installed a new automatic in-line continuous feed powder coating system