Sandblasting is an essential process to remove oxidation, scale, paint or other impurities. Sandblasting is also a key step for surfaces that have already been cleaned, ensuring the degree of coarseness that is necessary for subsequent painting.

All our free jet sandblasting systems allow manual blasting on metal surfaces such as steel, aluminium and brass, as well as on glass and ceramics. Particularly, Eurotherm booths can be fitted to sandblast stainless steel as well, by equipping the system with specific technical devices that avoid superficial pollution of the material to be treated.

In Eurotherm we design sandblasting booths with total or partial grit recovery. In such cases, the abrasive material dispersed on the ground in the sandblasting booth is recovered and separated from coarse waste and dust, in order to be used again. In this way, waste and preparation time for the following process are reduced. Our technical team will help you choose the best system for your company’s needs.

Our free jet blasting systems are custom-made: we take into account the spaces, needs and goals of our customers, in order to structure a product that is functional and respondent to all processing requirements.

Sandblasting systems 4.0

Eurotherm engineers are at the forefront of 4.0 sandblasting equipment, designed to be connected to production lines in full compliance with the parameters required by the regulations of the Transition Plan 4.0.

Revamping of sandblast booths

Revamping sandblasting cabins is an intervention to overhaul existing booths that have accumulated a state of wear over the years to the point of not being able to guarantee production performance.

If your company owns a particularly old booth, Eurotherm’s technical team will help you recover and refurbish the equipment.

Eurotherm sandblasting booths

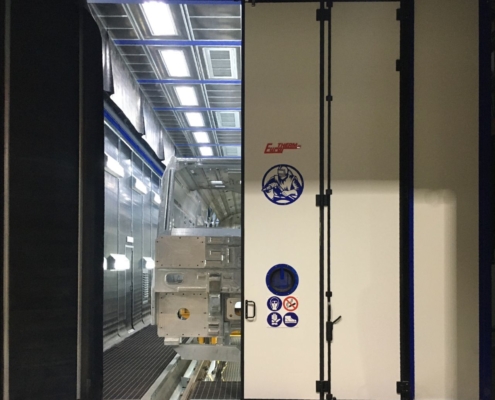

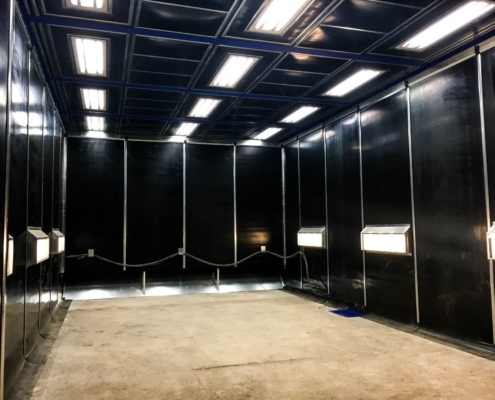

All our sandblasting booths are designed to treat products of any size. Inside the booths, the operator can perform blasting in absolute safety and efficiency.

The exclusive strong points of our sandblasting booths are:

- easy, cheap maintenance,

- total customization of the booths, as the systems can be made to measure, in order to to meet the most specific needs,

- rapid assembly,

- compliance with CE standards,

- evenly distributed lighting using LED lamps. This system, as well as helping to maintain the system’s high performance, leads to considerable energy savings and reduced maintenance costs,

- resistance and durability over time. The booth‘s inside (both the walls and the roof) is coated with anti-abrasive rubber, in order to protect the booth walls from the jets of abrasive material.

The booth is made of pre-painted, mineral wool pre-insulated panels, covered with anti-abrasive rubber and supported by a painted steel structure.

- acoustic insulation thanks to the use of 80 mm thick mineral wool panels, which reduce noise outside the booth,

- cleanliness inside the booth, thanks to the constant flow of air, made possible by an industrial dust suppressor. Our technical team will calculate the air flow’s reach of the sandblasting booth to perfection, in order to preserve maximum visibility as well as the operator’s safety.

- easy transport of the material by overhead crane, rail cart or overhead conveyor.

- safe working environment. Bright and clean, Eurotherm booths are also equipped with doors whose devices immediately stop the sandblasting process should the doors open.

Thanks to such design features, Eurotherm sandblasting booths provide a functional, insulated and clean working environment both inside and outside the booth.

Sandblasting systems with total or partial grit recovery

Sandblasting systems with partial or total grit recovery reduce or eliminate the need to prepare the working area, and allow the abrasive material to be recovered for further use, thus reducing waste.

A separator removes dust, coarse waste, or other impurities from the blasting grit, feeding it back in a continuous cycle into the silo, which will continue to supply the sandblaster during processing.

The grit recovery systems prevent the abrasive from accumulating during the process, also ensuring the operator to freely move around the environment in complete safety.

Eurotherm sandblasting systems can be equipped with two recovery modes:

- The total abrasive recovery systems use scrapers over the entire floor surface to lead the abrasive material into the grit recovery system.

This completely eliminates the time it takes to recover the abrasive from the floor, saving the staff a considerable amount of time that would otherwise be spent on manual recovery.

Depending on specific needs, they can be made

– with foundations, in which case recovery is carried out under the floor,

– without foundations, in which the total recovery is done in the same way as the system with foundations but, in this case, the recovery system is above ground level.

- The partial abrasive recovery system requires little construction work and is easy to install. At the end of the blasting operation, the abrasive dispersed on the chamber floor can be pushed manually into the conveyor hopper, from where it will be separated from dust and re-introduced into the process.

The choice between a sandblasting booth with a total or partial abrasive recovery system must take into account many aspects, such as: the type of processing, the size of the products and the space that is available. Our technicians will be able to advise you on the best solution for your needs.

Customized sandblasting systems

Eurotherm manufactures custom-made sandblasting equipment in order to solve any problem related to the sandblasting treatment of objects of any size.

Blasting booths are designed and assembled according to your actual needs, the products to be treated and the space where they will be located.

Our worldwide experience makes us a leader in the field of sandblasting booths.

Download the booth’s data sheet for more information or contact us for a customized quote.

Eurotherm case studies

Over the years, Eurotherm has emerged in the field of sandblasting booths by designing customized installations of great significance.

Here are some examples:

- since 2015 we have been manufacturing blast modules from standard ship containers;

- in 2016 we designed sandblasting booths on tensile structures;

- in 2019 we designed a surface preparation system (blasting, washing, drying) for train wheels in the Czech Republic and in 2020 we assembled a manual blasting booth for blasting railway carriages;

- we have also created booths with external operator stations for in-room work.

Shot peening machines

Shot peening machines are ideal for those who do not have dedicated space, yet wish to perform high quality blasting.

Eurotherm shot peening machines are available in two versions:

- Basic shot peening machine with internal rotating table

- TE shot peening machine with extractable rotating table

Download the shot peening machines data sheet for further information or contact us for a customized quote.

FAQs about Eurotherm blasting booths and systems

What do Eurotherm sandblasting booths consist of?

– modular sandblasting chamber

– Clemco sandblasting machine with remote control;

– grit recovery system and transfer to the sandblasting machine;

– dust suppressor;

– electrical panel;

– products handling system.

What are the dimensions of the sandblasting booths?

We mainly manufacture custom-made systems, designed to meet any production or space requirements. Our technical team will be able to counsel you best, from design to testing.

How do products enter the blasting booths?

Depending on your needs, the products can enter Eurotherm blasting booths by overhead cranes, rail carts or suspended rails.

Clemco original spare parts for sandblasting equipment

Our sandblasting machines are Clemco branded, as are all spare parts. You can conveniently purchase them in our shop or contact us at service@eurotherm.eu.

The Clemco equipment supplied with the sandblasting booth is generally as follows:

A CLEMCO sandblasting machine with remote control built according to current standards, for a maximum working pressure of 12 Bar. It is supplied complete with:

– 200 liter tank;

– handrail to facilitate inspections inside;

– wheels for easy movement;

– sandblasting cycle start and stop control with aluminum handle valve, equipped with safety blocking system and pneumatic circuit with double hose, to avoid any accidental start;

– 20 meters of double sheathed hose, complete with fittings for the double remote control;

– valve for abrasive;

– 24 v electro valve for door safety;

– exhaust silencer;

– door safety limit switch.

A sandblasting kit consisting of:

– 20 meters of abrasive tube Ø 25×40;

– hose holder for pipe;

– nozzle holder;

– tungsten carbide Venturi nozzle.

A protection kit for sandblasting composed of:

– 20 meters of air hose;

– a wide visor CE helmet with double rectangular safety glass and integrated cape;

– an active carbon filter with pressure regulator and pressure gauge.

Safety of sandblasting personnel

All our sandblasting booths are equipped with special devices to protect the safety of sandblasting operators, such as:

– Gun with “dead man” control;

– Blasting interdiction system in case of door opening or system anomaly;

– Breathing helmet.

What fields do Eurotherm sandblasting machines work for?

The main fields are industrial (light and heavy carpentry), railways, naval, piping – oil and gas, automotive, restoration.

What types of materials can sandblasting be performed on?

The variety of surfaces it is possible to sandblast on are many: aluminum, steel, cast iron, wood, ceramics, glass and marble are just some of the main ones. Our sandblasting equipment is also designed to work on stainless steel. In this case, the booth will be equipped with special measures to avoid pollution of the abrasive and of the surfaces to be treated.

What abrasive material can be used in sandblasting machines?

Any type of abrasive material can be used. The main abrasive materials we use are steel grit, stainless steel grit, red-brown or white corundum, glass or steel microspheres, ceramic microspheres, garnet and silica sand. It is also possible to sandblast with walnut shells or corn cob.

The abrasive material must be chosen depending on the surface to be sandblasted and the roughness to be achieved. Our technical department will support you in this choice, by following the technical steps of the sandblasting process step by step.

Is it also possible to sandblast inside pipes?

Yes, depending on the dimensions. There are special Clemco nozzles, designed to meet such needs.

Are Eurotherm blasting booths covered by warranty?

The booth and all the components are covered by warranty as per current regulations.

Are the sandblasting systems made with or without foundations?

They can be designed both ways, depending on your needs. If it is possible to carry out civil works, the scrapers for recovering the abrasive will be housed inside the foundations, while if this is not possible, a special base will be designed.

Sandblasting booths without foundations can be easily disassembled and reassembled in another location and can be a good solution for those companies that, for example, find themselves working in rented sheds or need to carry out special temporary work.

Our technical team can advise you on the best solution for your needs.

Are the blasting booths installed inside or outside the warehouse?

The booths, as well as the rest of the equipment, are designed to be installed indoors, with the exception of special cases for which we have also built booths in tensile structures.

Why choose a manual sandblasting system?

With a manual sandblasting system it is possible to abrade any type of surface with any shape, as it is the most flexible solution. With an automatic blasting system this is not possible: the maximum dimensions set for blasting a particular object cannot be changed.

Does Eurotherm also design complete workflows?

We design and build sandblasting booths that can be assembled in line with the paint process and the ovens, to ensure a complete workflow, depending on the customer’s needs.

Eurotherm creates innovative solutions to meet all needs.

Contact us and tell us about your business for a customized quote.