Eurotherm liquid coating plants are designed to adapt to any company production requirement.

In fact, the systems are designed with the utmost attention to the quality of the final product’s coating, by making sure that dust or other impurities do not pollute the inside of the system.

With this in mind, great importance is also bestowed upon optimizing the working cycle, which is necessary to guarantee greater management flexibility, reduce waste and allow high energy savings.

Finally, we adopt all the most innovative technologies to ensure full compliance with environmental regulations and with the safety of the working environment.

It is with such consideration in mind that we offer our clients effective, high-performance and long-lasting liquid coating systems.

4.0 liquid coating systems

Eurotherm liquid coating systems are designed to allow the control of the status and operation of the individual machines at any time, while reporting anomalies and the progress of the work.

The systems are designed to be connected to production lines in full compliance with the parameters required by the regulations of the Transition Plan 4.0.

What does a liquid coating system consist of?

We could say that in Eurotherm there is no such thing as a “standard system”, but rather that each liquid coating system is created by taking into consideration the specific needs of each company: from the type of pieces to be painted to the available space, from the quality of the desired finish to the material to be treated.

In general, the components that can compose a liquid coating system are:

– Automatic washing tunnel

Through the chemical aggression during the washing phases, the surface of the piece is prepared for the subsequent coating phase.

We recommend to check out the page about Eurotherm washing tunnels for further information.

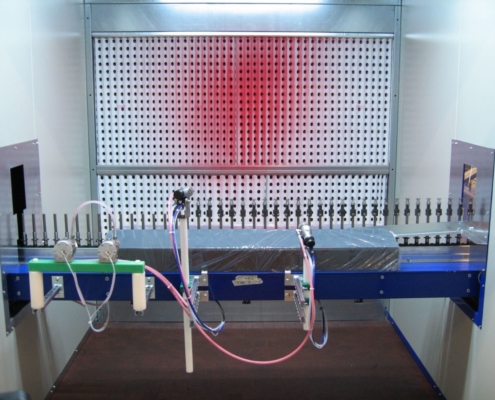

– Dry or water-based liquid coating booth

Both these types of cabins can be easily integrated into liquid coating systems with step-by-step or non-stop automatic feed.

Broadly speaking, dry painting booths are more suitable for systems with a reduced production rate, while liquid-based cabins are more suitable for painting large batches with high production rates.

We recommend to check out the page about Eurotherm liquid coating booths for further information.

– Drying tunnel and drying oven

The drying tunnel located at the exit of the washing tunnel and the desiccation oven inserted at the end of the liquid coating cycle are both equipped with an independent heat generator. In the case of the drying tunnel, the purpose is to dry the surface of the pieces in order to prepare them for the subsequent coating, while the meaning of the desiccation oven is to allow the water-based or solvent-based coating to dry more quickly in order to remove the pieces from the line without slowing down.

Drying tunnels and drying ovens normally handle temperatures of between 60°C and 120°C.

We recommend to check out the page about Eurotherm Drying Ovens for further information.

– Overhead conveyor

The heart of the liquid coating system is, in fact, the overhead conveyor, which is the connecting element between all the machinery, allowing the piece to proceed in sequence through all the phases of processing.

The pieces hanging from the conveyor’s gauges are moved without ever having to be removed, thus increasing the system’s efficiency and reduce downtime between processes.

In step-by-step plants, we usually use a two-rail conveyor that manages the individual gauges, by transporting the pieces to the various areas “on demand”, while in in-line systems we use a monorail conveyor with non-stop feed.

Step-by-step liquid coating systems

In step-by-step liquid coating systems, the different processing areas of the piece are separated by automatic doors. The automatic handling of the pieces is handled by the two-rail conveyor.

As well as preventing the dispersion of heat outside and helping to reduce the system’s energy costs, the doors also increase insulation between the areas, thus making the system more compact in size.

Non-stop liquid coating systems

In non-stop liquid coating systems, the piece to be treated is loaded directly onto the monorail conveyor in order for it to undergo, in sequence, all the processing phases without ever stopping until the pieces are unloaded.

The automatic transport system of the pieces and the absence of doors delimiting the different working areas contribute to maintaining a continuous work flow.

Such features make these systems the fastest way to process large batches of parts on a large scale without numerous color changes.

Eurotherm case studies

- Complete automatic system for the liquid coating of small/medium sized plastic components.

- Step-by-step system for the liquid coating of snow ploughs and ploughshares.

- Compact system for the automatic coating of drum brakes for a multinational company in the automotive industry.

- Liquid coating system for the new Jeep Compass.

- Highly compact in-line step-by-step liquid coating system.

- Liquid coating system with pieces handling by manually-operated overhead conveyor.

Eurotherm creates innovative solutions to meet all needs.

Contact us and tell us about your business for a customized quote.