- Premium features as standard supply

- Fully customised storage containers and technical paint preparation rooms

- Paint storage containers made from standard shipping containers

- Technical rooms for paint preparation and washing of paint guns

- Accessories for customising containers and preparation rooms

- Eurotherm case studies

Our storage containers originate from the need to store paints, thinners, solvents and all those flammable chemicals that are necessary for the preparation of liquid paint.

Over the years we have realised how this often underestimated aspect is becoming increasingly important, not only from a regulatory point of view (it is indeed a legal obligation to store flammable liquids properly) but also from an environmental point of view, and for this reason we have introduced a standard safety tank, the forced air exchange system and the high internal insulation.

The ongoing evolution of our automatic liquid paint systems has promoted the development of the integrated storage containers. The result was the construction of specific technical rooms, adjacent to the in-line liquid paint booths. The goal is to facilitate the mixing and dilution of the paints in order to feed the spray guns continuously, thanks to the integration of the standard pluses in our storage containers and the addition of further accessories with highly customisable specific features upon request.

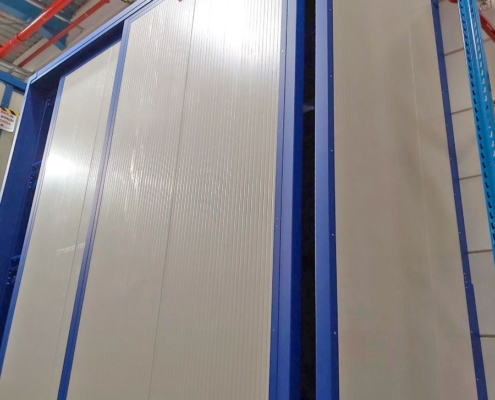

The distinctive feature of Eurotherm’s storage containers and paint preparation rooms is that they are entirely made-to-measure and engineered on a modular basis, in order to meet any dimensional and accessory customisation requirements, a philosophy that identifies all our production.

Premium features as standard supply:

- High thermal and acoustic insulation: doors, walls and roof are made of sandwich panels insulated with high-density mineral wool.

- Accidental spillage containment: there is always a watertight safety containment tank (retention tank) below the raised floor level, which, in the case of paint storage containers, is large enough to hold one third of the stored liquids, in accordance with European standards.

- Air recirculation: the correct exchange of inside air is always ensured by two or more air vents.

- Internal shelving: we produce specific shelves suitable for supporting heavy loads that allow for the homogeneous recirculation of air and avoid dangerous paint stagnation on the shelves. The shelves can be configured as desired to achieve the desired organisation.

Fully customised storage containers and technical paint preparation rooms

All Eurotherm storage containers and paint preparation rooms are manufactured taking the following parameters into account:

- The available space. Based on the required dimensions, Eurotherm technicians study the exact dimensions of the module, which is made entirely to measure.

- The required storage capacity. The layout of the shelves and their size depend on the type and quantity of material the customer expects to store inside, such as paint cans, barrels, cubitainers or others.

- The final destination. It is particularly important to know whether the container is to be placed inside or outside the factory, so that a weatherproof solution can be envisaged in the case.

The construction is generally assembled in one piece and factory-tested. All that is needed is a forklift to unload and position the module at the designated location and connect it to the power supply if necessary.

Paint storage containers made from standard shipping containers

This is a solution to be considered in the event of special requirements, the main advantages being:

- the load-bearing structure,

- the high resistance to weather elements,

- the robustness,

- all the intrinsic characteristics of shipping containers.

The disadvantages, on the other hand, are given by the standard dimensions of ship containers, which are available in two lengths only (20 and 40 feet). Despite this, they can be customised in almost the same way and with the same accessories as our made-to-measure containers.

Technical rooms for paint preparation and washing of paint guns

This type of room emerges from the need to have an environment that is suitable for mixing the different chemical products that are extremely volatile. This gave rise to a new type of room which, using the same construction and safety criteria borrowed from storage containers, raises their standards, as well as ergonomics, to ensure a comfortable and safe environment for the personnel working inside of it.

The technical preparation rooms are generally located near the spray booths. In these rooms, in addition to storing the paint, the operator usually washes the guns and mixes the chemicals to prepare the paint for actual use.

Beside the construction features borrowed from storage containers, the technical paint preparation rooms are additionally equipped with some standard features:

- Stainless steel worktop;

- Stainless steel sink;

- Suction wall to completely cover the worktop;

- Fume extractor fan with high flow rate to ensure forced air exchange and avoid dangerous concentrations of solvents in the air;

- Pedestrian grid floor;

- Containment tank under the grid;

- Lighting lamps;

- Doors and walls with large mirrors to promote lighting and operator safety inside;

- Access ramp to facilitate internal accessibility;

- Customised shelving for storing material.

Value saver technical rooms

Eurotherm can also supply an economical version of the technical rooms, value saver, made using galvanised or painted sheet metal panels (instead of pre-insulated panels), for the walls, roof and door, which are bolted and sealed together tightly and also serve as a supporting structure.

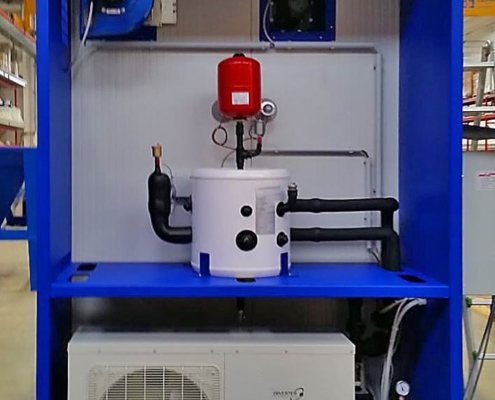

Technical rooms for paint gun pumps

For automatic liquid coating systems, a technical room version is also available to house the pumps, mixers and all accessories serving the automatic paint guns.

Accessories for customising containers and preparation rooms

Many accessories are available to customise Eurotherm storage containers and paint preparation rooms to the maximum extent:

- High-density mineral wool insulated walls, available in various thicknesses and fire resistance classes;

- Watertight safety tank;

- Air-conditioning system to maintain the desired temperature inside;

- Electric antifreeze heating system;

- Sliding or hinged doors;

- Lights for interior lighting;

- Extractor fan for forced air exchange;

- Steel shelves to organise the interior space;

- Automatic fire extinguishing system;

- Outdoor version with watertight roof and gutter to ensure proper rainwater runoff.

Eurotherm creates innovative solutions to meet all needs.

Contact us and tell us about your business for a customized quote.