We have recently designed this rotational system, specifically for the pre-treatment and painting of small tableware components, for one of the most iconic French companies with a strong tradition of excellence, quality and innovation.

The objects to be treated are, specifically, pepper and salt mills of various shapes and sizes, handmade in wood.

The peculiarity of the system: the brushing machines

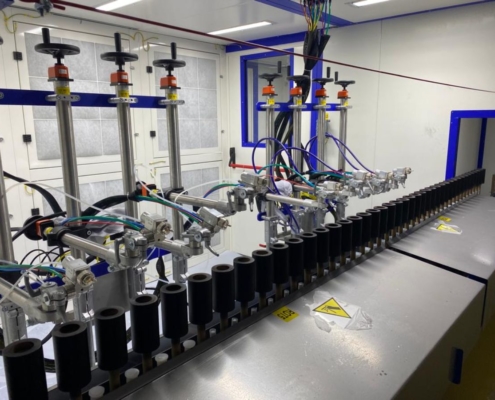

The painting line supplied to the company is designed to paint with a rotational system, but presents a peculiarity: there are two very complex machines for brushing wood. In fact, these machines are capable of adjusting the width or oscillation of the brushing treatment fully automatically, depending on the pieces to be treated.

The rotational painting system with high production rate supplied by Eurotherm

The rotational painting system we supplied involves a cycle composed of:

- Brushing 1

- Blowing / Ionising

- Primer painting

- Drying

- Brushing 2

- Blowing / Ionising

- Intermediate painting

- Drying

- Finishing painting

- Final drying

Whatever the production requirements, we can supply and integrate, within the same system, the customised solution that is most suited to the specific technological process that is required.