Revamping Colortec 2: Transformation of the painting plant with an old production style into an anticorrosion company

The revamping of the plant involved the integration of an osmosis system for the production of high-quality water for rinsing and of a tank for no-rinse passivation in the pre-treatment line, of a sandwich PVC cabin for the application of the primer, and of a high temperature RHT infrared pre curing oven, positioned before the finishing application booth.

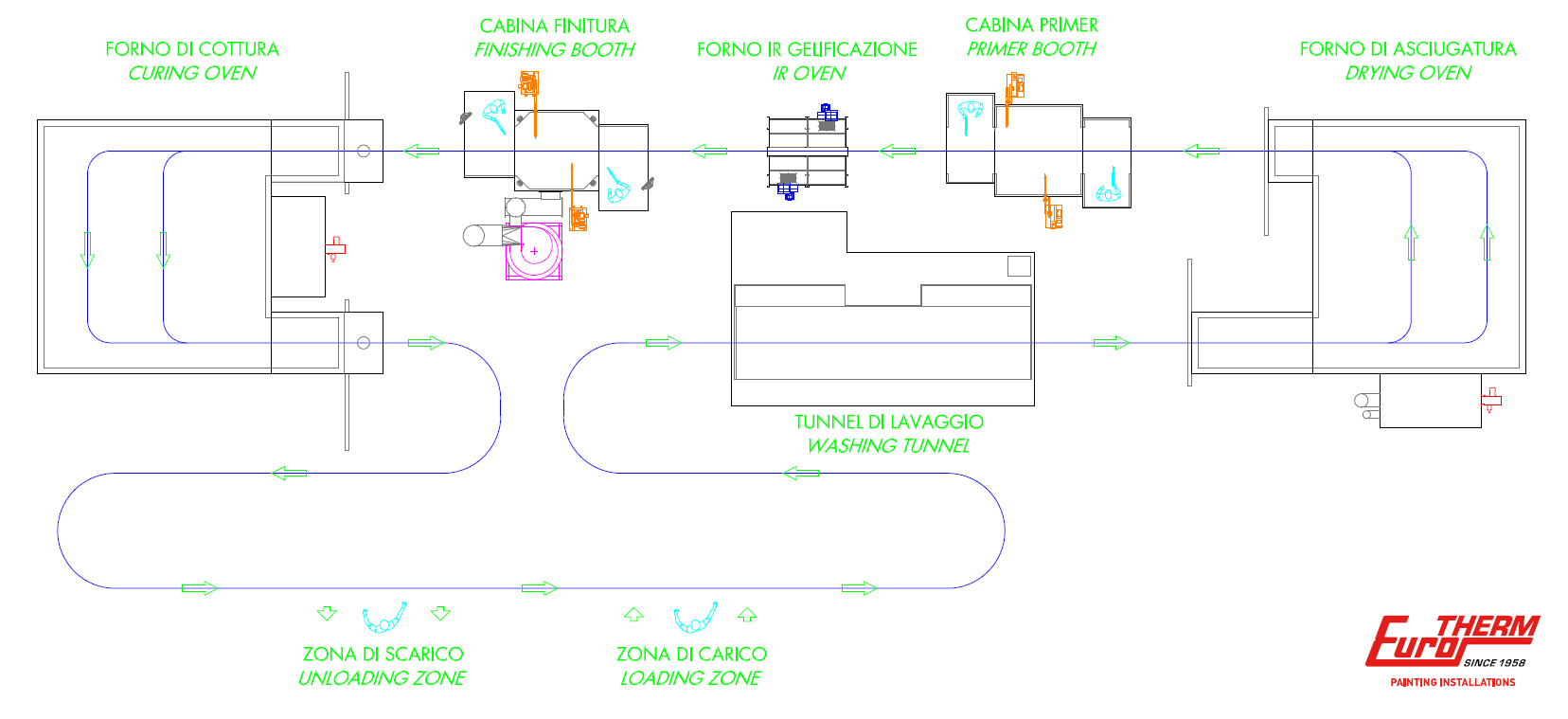

Description of the new production cycle:

- Automatic shot blasting machine with belt feeding using stainless steel grit for galvanized sheet

- Washing tunnel: Implementation from 2 stages to 4 stages:

-

- Phosphodegreasing

- Rinsing

- Pure osmosis rinse

- Passivation no rinse

- Drying oven

- PVC Primer booth

- IR oven for Pre-gelification

- PVC Top coat booth, equipped with cyclone with vibrating screen for dust recovery and color center for quick RAL change

- Curing oven

In this way we can ensure the anti-corrosion process for our plants and our customers. Colortec 2 is the subsidiary of Eurotherm S.p.A. for the painting of its artifacts.

ColorTec Indicative layout