In recent years Eurotherm has introduced highly specialized personnel in the programming of Siemens PLCs and touch-screen synoptic panels to expand and simplify the functionality of use of painting, shot blasting, washing booths, ovens and complete painting systems.

A strategic move driven by ambitious objectives, aimed at improving the functionality of current electrical panels, making them more flexible, accessible remotely and fully compliant with the standards of current and future Industry 4.0.

Eurotherm’s digital control panels basically offer advanced programming to allow the systems to communicate with the production line and management software.

The advanced functions of PLCs and touch-screen synoptics

Thanks to staff specialized in programming Siemens PLCs and touch-screen synoptic panels we can guarantee:

More features

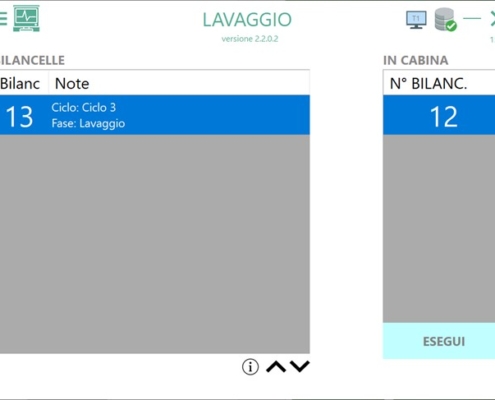

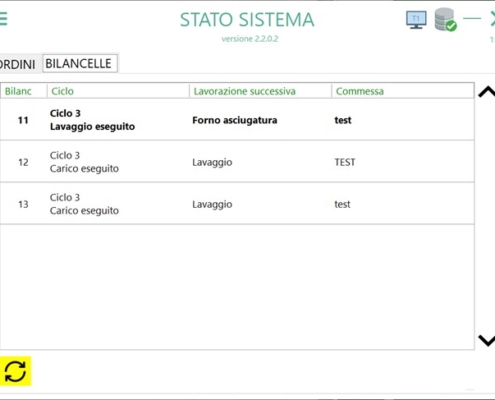

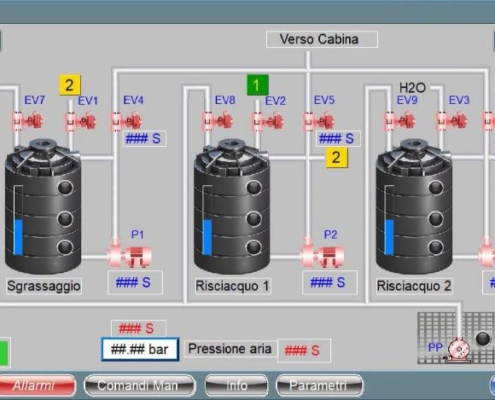

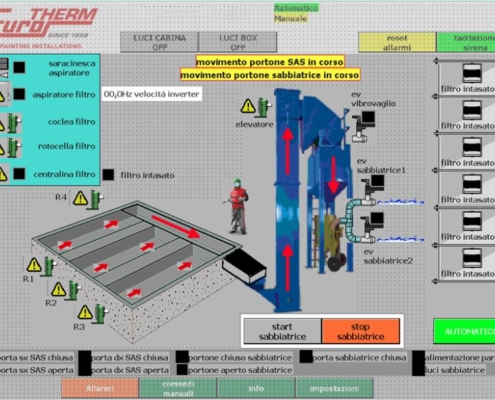

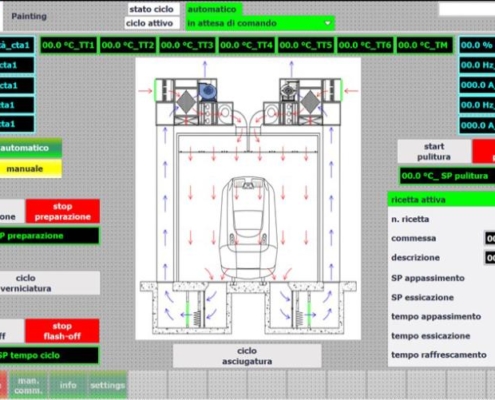

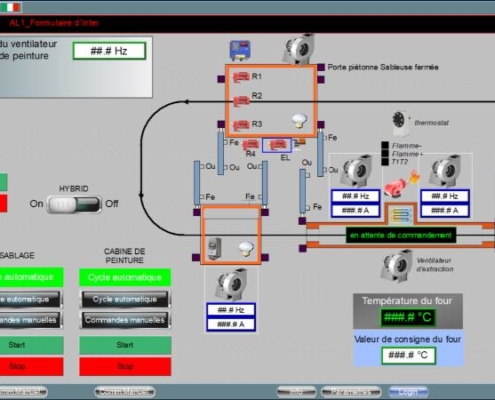

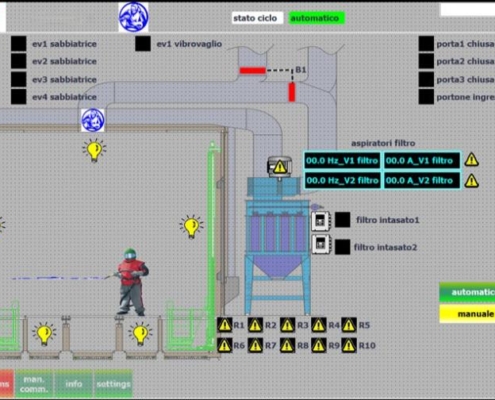

The implementation of a PLC in the plant allows you to enhance the functionality and at the same time simplify the management of the work process , transforming a simple control panel into an intelligent device, capable of carrying out all the operations required by the process automatically and in total autonomy.

Total customization

Customization at Eurotherm is a way of life: there is no booth or system that is produced without the customer’s needs having been assessed in terms of space, quality of finish and production objectives.

A flexibility that now also passes through the possibility of adapting PLCs and touch-screen synoptics to multiple industrial needs, managing to offer highly customized solutions that can be integrated with the rest of the automation present in the production plant.

Simplicity of management

There’s a lot of talk about Industry 4.0, but how accessible is all the technology they have at their disposal for companies? Starting from this question we committed ourselves to making the management process more accessible and easier to manage.

The touch-screen synoptics greatly simplify the man-machine interface , allowing operators to easily monitor the systems and, if necessary, make handovers intuitively, reducing the need for specialist training thanks to the use of a integrated management system.

Integrated remote assistance

The presence of the standard remote tele-assistance module , integrated into our PLCs, represents a further guarantee for the timely resolution of problems or malfunctions. Thanks to the possibility of interfacing remotely with the PLC it is possible to carry out rapid and efficient interventions, reducing production downtime to a minimum .

Industry 4.0 compliance

Thanks to the integration of a PLC with touch-screen synoptic in our electrical panels, our machines are in line with the principles of Industry 4.0 and beyond . A step forward towards digital transformation and adaptations to the continuously dynamic industrial system.

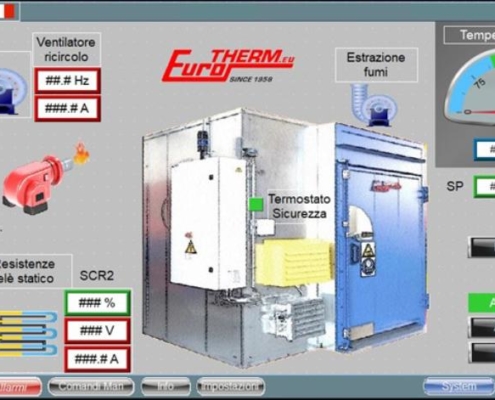

The Eurotherm case study: oven control panels

If in the past our ovens had an electromechanical panel with thermoregulator and minute timers as their basis, starting from 2022 we have introduced a completely digital control panel via SIEMENS PLC as standard on all ovens and subsequently on all booths and washing tunnels .

Starting from 2022, Eurotherm’s drying and polymerization ovens come standard with :

- digital control panel with Siemens PLC ;

- full touch screen panel ;

- preparation for data exchange as required by the legislation of the Capital Goods Plan ( Industry 4.0 ).