The transition towards Industry 5.0 is a reality .

It is clear that we are facing a new industrial era characterized, on the one hand, by the need to adopt advanced technologies to remain competitive on a global scale, and, on the other, by the need to look at the sustainability of one’s choices.

Polymerization ovens for Industry 5.0

In the context of industrial surface treatments, curing paints in ovens is certainly among the operations that have the greatest impact on a company’s energy expenditure.

Over the years, Eurotherm has introduced various optimizations in our ovens in order to focus on energy savings in a decisive manner. There was no talk yet of Industry 5.0, but the need to create highly energy-saving painting systems was already clear to Eurotherm’s technicians.

In this area, the following improvements have been made over time:

- Improvement of insulation ;

- Insertion of extraction hoods to recover heat coming out of the silhouettes in the curing tunnels;

- Use of natural gas burners that are more stringent than the reference environmental regulations;

- Extracted heat recovery system for recovery of up to 40% of the extracted heat.

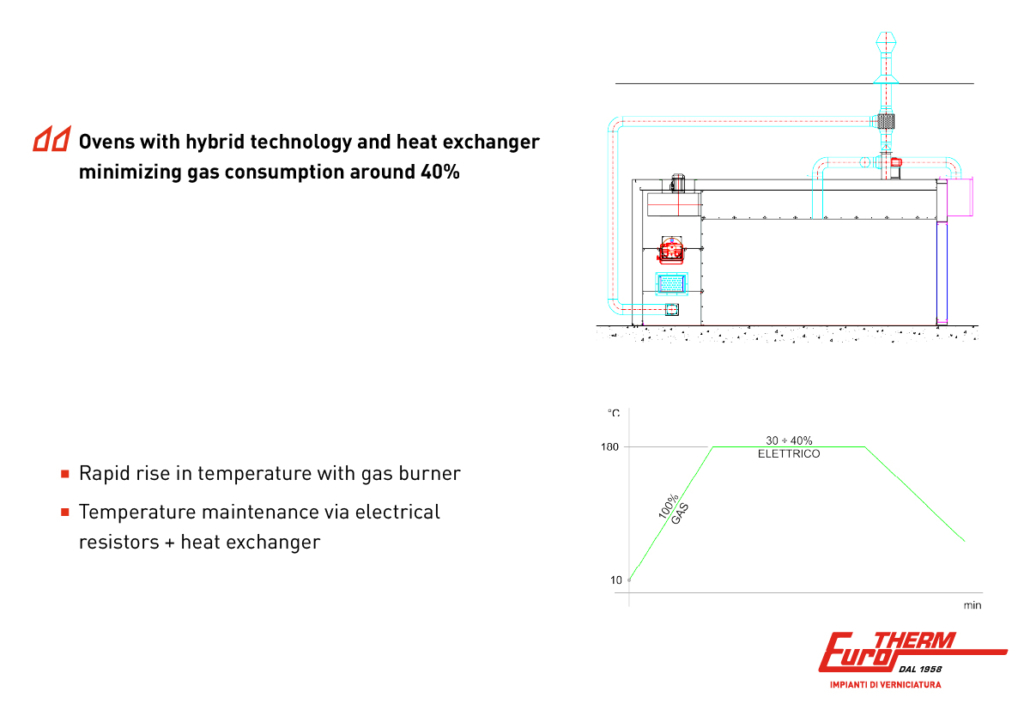

Eurotherm hybrid ovens

Eurotherm hybrid ovens are ovens that use both gas and electricity. This solution combines the two heating systems, gas and electric , within the same system. In addition to the gas burner in the air vein, there is in fact a series of electric batteries with a modulation system by means of static relays.

In this way the oven is brought to the working temperature by exploiting the power of the burner and once the temperature has been reached this is turned off by making the electric battery come into operation to maintain the set temperature . In combination with this system, a cross-flow heat recuperator is also added in order to recycle a large part of the heat extracted during the work cycle.

With this solution the quantifiable saving is more than 15% per batch compared to a traditional oven.

From this perspective, having the possibility of exploiting the electricity coming from photovoltaic panels makes the solution even more convenient.

Integration into Industry 5.0

All Eurotherm ovens integrate perfectly within the new Transition Decree 5.0 (exceeding what is required) because they offer:

- Energy efficiency , reducing consumption and optimizing operating costs and environmental sustainability;

- Advanced control , thanks to Siemens PLC control panel technology;

- Operational flexibility , improving the workflows of specific applications because they are created based on the individual needs of companies.

Eurotherm polymerization and drying ovens are the ideal investment for companies that want to access the funds of the Transition Decree 5.0 to modernize their production cycle and therefore improve their competitiveness.