How important is the control panel for a drying or curing oven? At Eurotherm, we believe it has now become an essential aspect, so much so that this year we decided to introduce advanced technology as a basic feature on all our ovens, and we are working on integrating it by default on all our painting, blasting and washing booths as well.

While in the past our custom-made drying and curing ovens had an electromechanical control panel with separate temperature controller and timer as a base, as of the end of 2022 Eurotherm’s basic model has evolved to a fully digital control panel model via SIEMENS PLC.

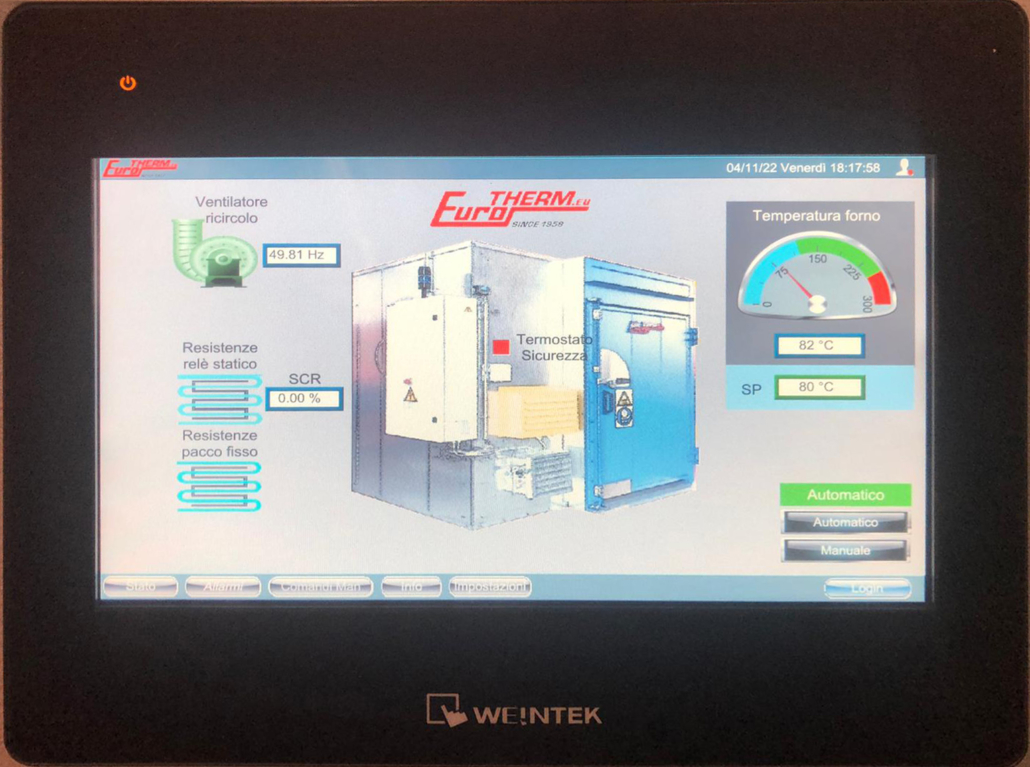

The details of the digital control panel

From 2022, Eurotherm drying and curing ovens come with standard:

- digital control panel with Siemens PLC;

- full touch screen panel;

- provision for integrating the parameters required by the Capital Goods Plan (Industry 4.0).

Something new that tells not only how production methods and technologies are changing, but above all how customers’ needs are evolving, with the interconnection of systems to the production line and management software as a priority.

How does the control software work?

The real innovation lies in the fact that the control software can be customised according to the customer’s requirements. SInce we focus on the customisation of each of our systems, for Eurotherm this was a fundamental step in order to be able to provide a finished product that is truly tailor-made. This is why we have recently added two software programming experts to our staff, so we can operate the PLC configuration in total autonomy, even remotely, to meet any current or future needs.

An innovation that relates to technological advances, changing customer demands, but also Eurotherm’s ability to adapt quickly and efficiently with cutting-edge solutions.