Annealing ovens provide a heat treatment that reduces the internal stresses of the material, without changing the structure, properties and dimensions of the part itself. In the automotive sector, in fact, the quality and reliability of components are essential to guarantee the safety and durability of vehicle performance.

In this context, one of the main challenges is to ensure that the materials used do not present internal tensions that could compromise their integrity over time.

Annealing ovens in the automotive sector

Annealing ovens eliminate internal tensions in automotive lenses, improving their stability and durability over time. These ovens are designed to eliminate residual stress generated during the material processing and ensure the quality of the finished product.

These ovens are designed to perform the stress-relief heat treatment on plastic materials in order to eliminate internal stresses generated during previous manufacturing processes such as molding. This process, known as Annealing, involves the controlled heating of the component to a temperature close to 90°C for about 15 minutes and then allowing it to cool to room temperature.

At Eurotherm we know how essential this treatment is in the automotive sector, to reduce the risk of cracks or breakages , throughout the life cycle of the lenses applied to car headlights.

The annealing ovens intended for the automotive sector have advanced technical specifications to meet the production and quality needs of the sector.

Maintaining uniformity of lens temperature throughout the annealing process is the fundamental step to ensure that the entire component is treated homogeneously, thus ensuring greater durability over time.

Eurotherm solutions for annealing of parts

Eurotherm provides tailor-made solutions for the annealing of parts in the automotive sector, an industry that is increasingly using advanced materials and high-performance technologies. Our cutting-edge technology solutions can significantly contribute to raising the quality standards of the industry, ensuring reliable and safe components for the global market.

Eurotherm annealing ovens are equipped with:

- temperature control and management systems on multiple oven zones,

- thermal uniformity management mechanisms to ensure uniform treatment of parts.

heating phase of the annealing oven, the temperature increases gradually, in relation to the thickness, size and characteristics of the product, until it reaches the required temperature which is maintained, without variation , for the entire duration of the process so that the different thicknesses of the component can be reached uniformly.

Eurotherm Installations for Annealing ovens

In this, Eurotherm has always stood out for its custom design : each Annealing oven is adapted to the specific needs of the customer, guaranteeing efficiency and performance.

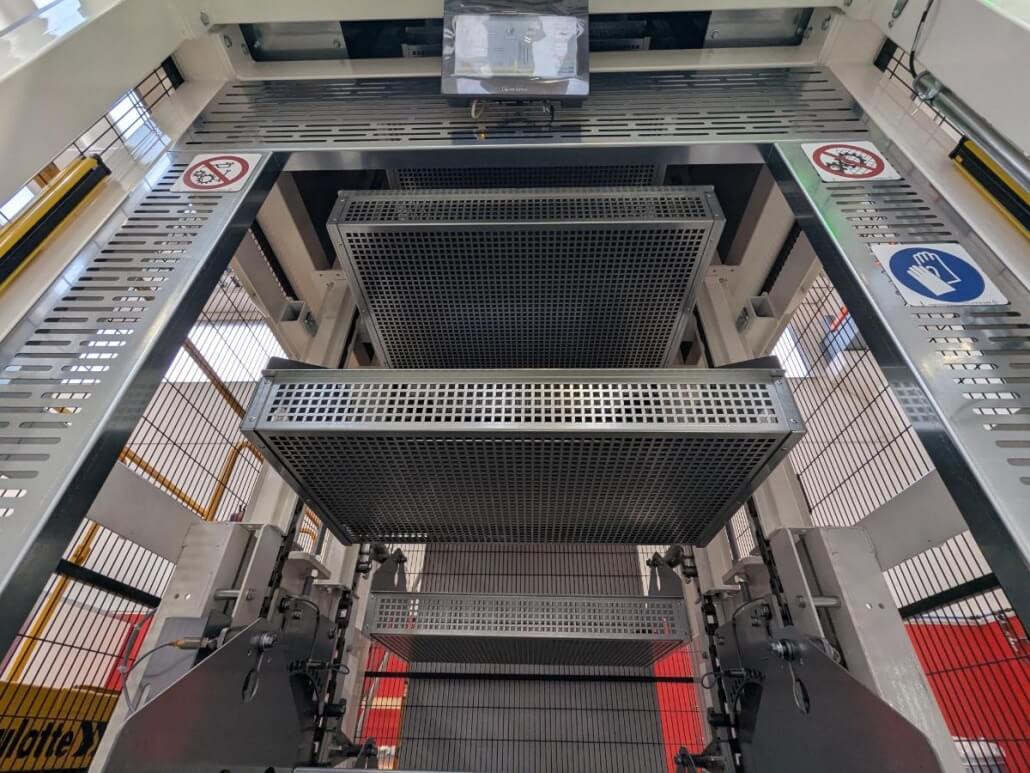

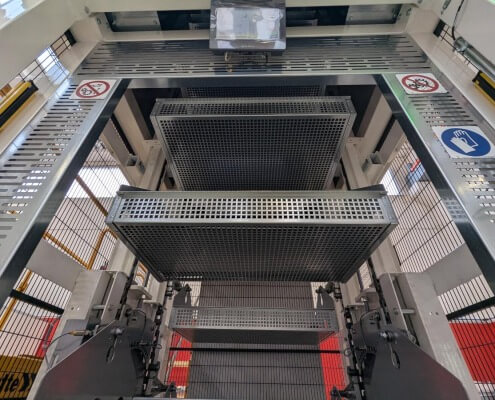

Like this Annealing oven for automotive headlights designed and installed for a world-leading company. It is a 27-meter-long oven installed 3.5 meters above the ground , equipped with an automatic conveyor that transports the lenses to be treated, ensuring an efficient and uniform process.

In this recent installation, the lens Annealing oven, heated by batteries of electrical resistances, ensures a constant temperature through 6 probes . Inside the oven there is an automatic conveyor with drawers and Step-by-Step movement capable of simultaneously managing 120 pieces with a Takt time of 30 seconds.

And what about this premium lens monoblock oven ? Making a high-precision Annealing oven with a temperature uniformity of ±2°C in a small space made the realization a challenge, as far as air flow management is concerned. We also respected the customer’s policy, which required a monoblock system so that it could be moved independently.

Whether you are a small business or a large international company, Eurotherm ovens and systems are always tailor-made to meet the specific needs of each company.