Eurotherm shotblasting booth for the nuclear sector

“With great power comes great responsibility.”

Those of you who have had a history with comic books will know we are talking about the classics, and will probably remember this famous phrase. It is an invitation to awareness and attention and to the consequences, a phrase that, in our opinion, goes perfectly with the world of nuclear energy – and the energetic uses of the atom in general.

What does nuclear power have to do with Eurotherm?

There is no energy… without waste to treat. To date, with the discussions underway on the energy crisis, on the comparison between renewable and non-renewables, on rising costs, on energy-intensive activities… nuclear energy is back on the table for debate.

The taste we had of this sector put us in contact with a central phase of the world of atomic energy: the management of radioactive waste and the remediation of abandoned plants and structures.

To respond to the requests of a company that works precisely in this delicate area, Eurotherm technicians dealt with the precision and delicacy required by interventions relating to the nuclear sector.

Let’s see the project.

The shotblasting booth for the nuclear sector

This is a classic case of revamping an existing shotblasting booth that never reached the standards required by the nuclear sector.

The particular sector of use, beyond the normal reconditioning activities, has required Eurotherm technicians to think about particular precautions aimed at:

- contain grit and fine dust,

- studying a customized system so that the possibility of contact between the operating personnel and the pieces to be machined was eliminated.

In particular, the measures implemented to fulfil this second request have provided for:

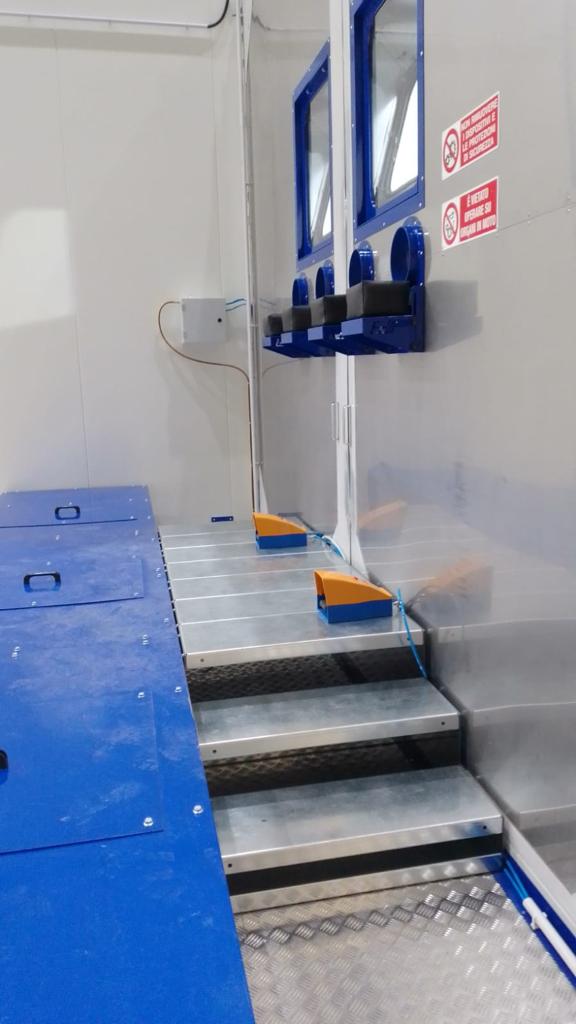

- the creation of 3 shotblasting stations outside the booth, with double portholes and insulation gloves,

- the study and construction of a motorized trolley, equipped with a rotary table up to 2,000 kg operated by a remote control, for the entry, processing and exit of the pieces from the booth,

- the creation of an automatic external door,

- the creation of a second door, always automatic, inside the cabin and designed for the compartmentalization of the processes,

- the creation of a grit recovery and containment system based on floor scrapers without civil works,

- the creation of an abrasive media regeneration system and the relative compartmentalised filter unit and with absolute filters.

With these modifications, the revamping of the booth has made it possible to better manage the shot blasting of the elements that have been in contact with radioactive materials.

Just a final curiosity: the shotblasting booth subject to revamping did not originally bear the Eurotherm brand. This case of revamping has therefore turned into a double challenge: on the one hand, relating to the management of a particularly delicate shot blasting phase, on the other… being linked to having to “enter” into a product designed by others.

Looking at the final result (and listening to the customer) we are sure that we have achieved the satisfaction of all parties!